Embarking on a creative sewing project is exhilarating, but encountering the frustration of skipped stitches on your sewing machine can quickly dampen the excitement. Imagine the disappointment of seeing your carefully planned design interrupted by this common issue. Fear not, as we delve into the art of troubleshooting.

Discovering how to fix skipped stitches on sewing machine is not just about technical know-how; it’s about empowering your creative journey. In this guide, we navigate through practical solutions to ensure your stitches flow seamlessly, allowing your artistic vision to flourish without the interruption of those pesky skipped stitches. Let’s unravel the mysteries and get back to the joy of crafting without a hitch.

Contents

- 1 TLDR

- 2 What Is a Sewing Machine and How Does It Work?

- 3 What are the Causes of Skipped Stitches on a Sewing Machine?

- 4 How to Fix Skipped Stitches on Sewing Machine?

- 5 Can You Fix a Sewing Machine Yourself?

- 6 Troubleshooting Common Sewing Machine Issues

- 7 Sewing Machine Maintenance Tips

- 8 Conclusion

- 9 References

- 10 Frequently Asked Questions

- 10.1 What are some common causes of skipped stitches on a sewing machine?

- 10.2 How often should I check and replace the needle on my sewing machine?

- 10.3 Can adjusting the tension on my sewing machine help to fix skipped stitches?

- 10.4 What type of lubricant should I use to clean and lubricate my sewing machine?

- 10.5 How can I test the stitch length and width on my sewing machine to ensure it is set correctly?

- 10.6 How will you correct a skipped stitches problem?

- 10.7 What is the cause of skip stitches in a sewing machine?

- 10.8 How do you fix a sewing machine that does not stitch?

TLDR

- Ensure you’re using the right needle for your fabric and replace it if it’s dull or bent.

- Check and adjust thread tension for balanced stitching, consulting your manual for guidance.

- Inspect bobbin winding and insertion, keeping the bobbin area clean from lint and debris.

- Use high-quality thread, match needle and thread types, and perform regular machine maintenance for optimal performance.

What Is a Sewing Machine and How Does It Work?

A sewing machine is a versatile device designed to efficiently stitch fabric together, revolutionizing the way garments and textiles are created. Essentially, a sewing machine operates by creating a continuous stitch through the interlocking of a top thread and a bottom bobbin thread. The machine achieves this through a series of precise mechanisms.

At the heart of a sewing machine is the needle, which moves up and down rapidly, piercing the fabric. Simultaneously, the top thread is pulled through the needle, forming a loop. The bobbin, located beneath the fabric, releases the bottom thread, creating another loop. As the needle rises, the two loops intertwine, securing the fabric layers together. The feed dogs, small metal teeth, then move the fabric forward, ensuring a consistent stitch length.

To regulate the stitch length and tension, a sewing machine typically features adjustable controls. These controls allow users to customize their sewing projects according to the fabric type and desired outcome. For example, thicker fabrics may require a longer stitch length, while delicate materials might benefit from a shorter one. Understanding the machine’s settings and experimenting with different configurations empowers users to achieve optimal results.

In summary, a sewing machine simplifies the labor-intensive task of hand stitching by automating the process. It efficiently combines top and bottom threads, creating a secure and uniform stitch. With adjustable features, users can tailor their sewing machine’s settings to meet the specific demands of various fabrics, making it an indispensable tool in the world of textile craftsmanship.

What are the Causes of Skipped Stitches on a Sewing Machine?

Skipping stitches on your sewing machine can be frustrating, causing imperfections in your sewing projects. Several factors contribute to this issue, and understanding the common causes can help you troubleshoot and resolve the problem.

- Needle Issues: A dull or bent needle can lead to skipped stitches.

- Thread Tension: Incorrect tension, either too tight or too loose, can result in skipped stitches.

- Bobbin Problems: A poorly wound or incorrectly inserted bobbin can cause stitching irregularities.

- Machine Maintenance: Lack of proper maintenance, such as accumulated lint or debris in the bobbin area, can interfere with smooth stitching.

- Incorrect Thread: Using low-quality or old thread may lead to stitching problems.

- Machine Speed: Sewing too fast or too slow can impact stitch formation.

- Fabric Choice: Certain fabrics, like knits or stretchy materials, may require special handling.

- Needle and Thread Compatibility: Ensure that the needle and thread you’re using are compatible. Mismatched combinations can lead to skipped stitches.

By addressing these common causes, you can improve the stitching performance of your sewing machine. If needed, refer to your machine’s manual for specific guidelines on maintenance and troubleshooting.

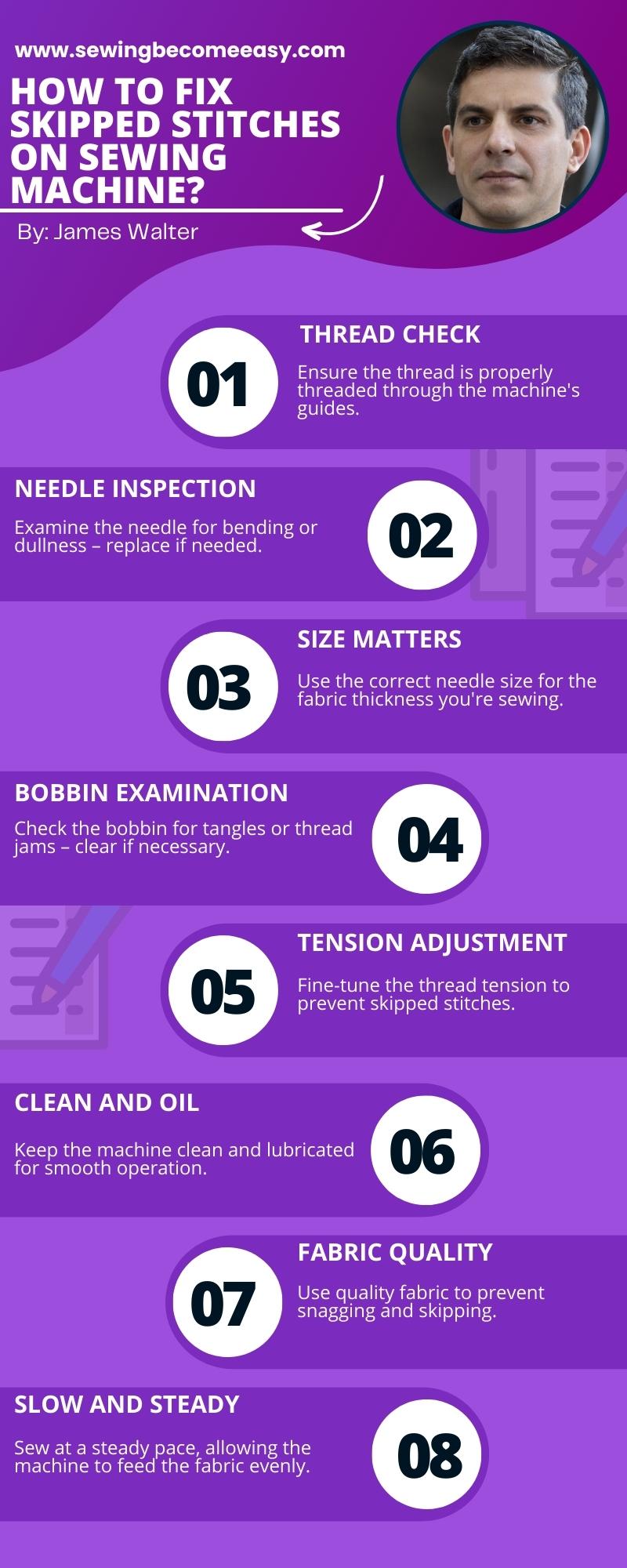

How to Fix Skipped Stitches on Sewing Machine?

If your sewing machine is skipping stitches, don’t worry; there are practical steps you can take to resolve this issue and get back to smooth, even stitching. Follow these troubleshooting steps to identify and fix the problem.

- Check Needle Condition:

- Ensure you are using the correct needle for your fabric.

- Replace the needle if it’s bent or dull.

- Adjust Thread Tension:

- Examine the thread tension settings and make necessary adjustments.

- A balanced tension ensures proper stitching; consult your manual for guidance.

- Inspect Bobbin and Bobbin Case:

- Verify the bobbin is wound evenly and inserted correctly.

- Clean the bobbin case area for any lint or debris.

- Perform Machine Maintenance:

- Regularly clean and oil your sewing machine as instructed in the manual.

- Remove lint and dust from the feed dogs and other key areas.

- Use High-Quality Thread:

- Opt for good-quality, fresh thread to prevent thread-related issues.

- Ensure the thread is compatible with the needle and fabric.

- Check Stitching Speed:

- Adjust your sewing speed to find a comfortable and consistent pace.

- Avoid sewing too fast, especially when working with challenging fabrics.

- Evaluate Fabric Type:

- Adjust machine settings for different fabric types, especially stretchy or delicate materials.

- Experiment with stitch length and width to find the optimal settings.

- Confirm Needle and Thread Compatibility:

- Ensure the needle and thread are compatible in size and type.

- Mismatched combinations can lead to stitching problems.

It is worth mentioning that before starting your actual project, test stitch on a scrap piece of fabric to check for issues as this allows you to fine-tune settings without affecting your project.

Let’s discuss these fixes in detail now.

1. Check Needle Condition:

A crucial step in resolving stitching issues is ensuring your needle is in optimal condition. A dull or bent needle can result in irregular stitches and skipped stitches. Here’s a step-by-step guide to checking and addressing needle-related problems:

- Select the Right Needle:

- Confirm you are using the correct needle for the fabric you are working with. Different fabrics require different needle types and sizes.

- Inspect the Needle:

- Examine the needle for any signs of damage, such as bends or bluntness.

- If the needle is damaged, replace it with a new one that matches the fabric and project requirements.

- Needle Size Matters:

- Ensure the needle size corresponds to the thickness of the fabric. Using a needle that is too small for heavy fabric or too large for delicate fabric can result in skipped stitches.

- Needle Installation:

- Properly insert the needle into the needle holder, ensuring it is fully seated and facing the correct direction.

- Tighten the needle screw securely to prevent any wobbling during stitching.

2. Adjust Thread Tension:

Incorrect thread tension can cause a variety of stitching problems, including skipped stitches. Achieving the right balance is crucial for a smooth sewing experience. Follow these steps to adjust thread tension:

- Refer to the Manual:

- Consult your sewing machine manual for information on adjusting thread tension specific to your model.

- Thread the Machine Correctly:

- Ensure the thread is correctly threaded through the machine, including the tension disks.

- Check for any thread snags or knots that might impede smooth thread flow.

- Test on Scrap Fabric:

- Stitch on a scrap piece of fabric and observe the stitches.

- If the stitches appear too tight or too loose, make incremental adjustments to the thread tension and retest until you achieve balanced stitches.

- Upper Thread Tension Dial:

- Adjust the upper thread tension dial based on your observations. Turning the dial to a higher number increases tension, while a lower number decreases tension.

- Bobbin Tension Check:

- Ensure the bobbin is loaded correctly and threaded properly.

- Some machines allow for adjusting the bobbin tension; refer to the manual for guidance on your specific model.

3. Inspect Bobbin and Bobbin Case:

Issues with the bobbin and its case can lead to stitching irregularities. Follow these steps to inspect and address problems related to the bobbin:

- Bobbin Winding:

- Ensure the bobbin is wound evenly and smoothly. Uneven winding can cause disruptions in thread tension.

- Check the bobbin thread for any tangles or knots. Rewind the bobbin if necessary.

- Bobbin Insertion:

- Confirm that the bobbin is inserted correctly into the bobbin case. Follow your machine’s manual for the proper orientation.

- Make sure the bobbin case is securely in place. Loose bobbin cases can lead to erratic stitching.

- Bobbin Tension:

- Some sewing machines allow for adjusting the bobbin tension. If needed, consult your manual for instructions on adjusting the bobbin tension to achieve optimal stitching.

- Clean the Bobbin Area:

- Regularly clean the bobbin area for lint, dust, or stray threads. Accumulated debris can affect the smooth movement of the bobbin, causing stitching issues.

- Use a small brush or the provided cleaning tools to gently remove any lint or debris.

4. Perform Machine Maintenance:

Proper maintenance is essential for the smooth operation of your sewing machine. Regular cleaning and lubrication prevent issues that can lead to skipped stitches. Here’s a step-by-step guide for routine machine maintenance:

- Refer to the Manual:

- Consult your machine’s manual for specific maintenance guidelines and recommended cleaning procedures.

- Turn Off and Unplug:

- Before performing any maintenance, turn off your sewing machine and unplug it from the power source for safety.

- Clean the Feed Dogs:

- Lift the presser foot to expose the feed dogs.

- Use a brush or the provided cleaning tools to remove any lint or debris from between the feed dogs.

- Oil Moving Parts:

- Follow the manual’s instructions for oiling the moving parts of your sewing machine. Lubricating key components ensures smooth operation.

- Use only the recommended sewing machine oil and apply it sparingly.

- Check for Loose Screws:

- Inspect the machine for any loose screws or bolts. Tighten them if necessary to eliminate vibrations that could affect stitching.

- Inspect the Needle Plate:

- Remove the needle plate and clean any accumulated debris underneath.

- Ensure the needle plate is securely reinstalled after cleaning.

5. Use High-Quality Thread:

The choice of thread plays a crucial role in achieving consistent and skip-free stitches. Follow these steps to ensure you are using high-quality thread:

- Thread Compatibility:

- Ensure that the thread you are using is compatible with your sewing machine and suitable for the fabric you are working with.

- Check the thread weight and fiber content to match the recommended specifications in your machine’s manual.

- Fresh Thread:

- Use fresh thread to avoid issues caused by old or weakened thread. Over time, thread can deteriorate and become more prone to breakage or skipping.

- Store thread in a cool, dry place away from direct sunlight to maintain its quality.

- Thread Path Inspection:

- Check the entire thread path, including the spool, guides, and tension disks, for any snags or obstructions.

- Make sure the thread is smoothly unwinding from the spool during sewing.

- Thread Tension Adjustment:

- If you’ve confirmed the thread quality and still experience issues, revisit the thread tension settings. Adjust the tension as needed to achieve balanced stitches.

6. Check Stitching Speed:

The stitching speed at which you operate your sewing machine can impact the formation of stitches. Follow these steps to find the optimal stitching speed and reduce the likelihood of skipped stitches:

- Practice on Scrap Fabric:

- Stitch on a scrap piece of fabric to practice and observe how the machine responds at different speeds.

- Find a comfortable and steady stitching pace that allows the machine to form stitches consistently.

- Avoid Excessive Speed:

- Sewing too fast may cause the needle to struggle to penetrate the fabric, leading to skipped stitches.

- Slow down the stitching speed, especially when working with challenging fabrics or intricate patterns.

- Adjust Foot Pressure:

- Some sewing machines allow you to adjust the foot pressure. Experiment with different foot pressure settings to find the one that works best for your project and reduces skipped stitches.

- Stitch Length and Width:

- Adjust the stitch length and width settings based on the fabric type. Finer fabrics may require shorter stitches, while heavier fabrics may benefit from longer stitches.

- Refer to your machine’s manual for recommendations on optimal stitch settings.

7. Evaluate Fabric Type:

Different fabrics require specific handling to prevent stitching issues. Follow these steps to adjust your machine settings based on the type of fabric you’re working with:

- Select the Right Stitch:

- Choose the appropriate stitch for the fabric type. Straight stitches work well for woven fabrics, while zigzag stitches are suitable for stretchy materials.

- Experiment with different stitches on scrap fabric to determine the one that produces the best results.

- Adjust Stitch Length and Width:

- Modify the stitch length and width settings based on the fabric’s characteristics. Finer fabrics may require shorter stitches, while thicker materials may benefit from longer stitches.

- Refer to your sewing machine manual for recommended settings for specific fabric types.

- Use a Walking Foot for Layers:

- When working with multiple layers of fabric or slippery materials, consider using a walking foot. This accessory helps feed the layers evenly, reducing the likelihood of skipped stitches.

- Stabilize Stretchy Fabrics:

- For stretchy fabrics like knits, use stabilizers or special knit interfacing to prevent distortion during sewing.

- Experiment with differential feed settings if your machine has this feature to improve stitch quality on stretch fabrics.

8. Confirm Needle and Thread Compatibility:

Mismatched needle and thread combinations can lead to stitching problems. Ensure compatibility by following these steps:

- Check Needle Size and Type:

- Verify that the needle size is appropriate for the fabric thickness. Fine fabrics may require smaller needles, while heavier fabrics need larger ones.

- Use ballpoint needles for knits and universal needles for general sewing.

- Thread-Needle Match:

- Ensure the thread thickness matches the needle eye size. Thick threads may require larger-eyed needles to prevent friction and breakage.

- Silk or delicate threads may require finer needles to avoid damage.

- Consider Thread Material:

- Different thread materials (cotton, polyester, silk) may require specific needle types for optimal performance.

- Consult your machine manual for recommendations on compatible needle and thread combinations.

- Test on Scrap Fabric:

- Before starting your actual project, test the chosen needle and thread combination on scrap fabric.

- Adjust as needed to achieve smooth and even stitches.

By systematically addressing these steps, you can often identify and resolve the factors causing your sewing machine to skip stitches. If the problem persists, consider seeking assistance from a professional technician.

Can You Fix a Sewing Machine Yourself?

Sewing machines are intricate devices, but many common issues can be addressed without professional help. Basic troubleshooting is often within reach for DIY enthusiasts. If your sewing machine is not stitching correctly, start by checking the needle. A bent or dull needle can cause uneven stitching or fabric damage. Replace it if needed, ensuring it’s the right size and type for your fabric.

Another common problem is thread tension. If stitches are too tight or too loose, adjust the tension dial following the machine’s manual. Ensure the bobbin is correctly threaded as well. Sometimes, lint or debris can accumulate in the bobbin case or around the feed dogs, causing issues. Regular cleaning with a small brush can prevent these problems.

If the machine is making unusual noises, investigate the bobbin area for loose parts or foreign objects. A jammed machine can often be resolved by removing the bobbin and rethreading the top thread. Remember to use the correct bobbin for your machine to avoid jams.

For more advanced issues or if you’re uncertain about a repair, it’s wise to consult your machine’s manual or seek guidance from online tutorials. Some repairs may require professional attention, but with careful observation and a willingness to learn, many sewing machine problems can be tackled successfully at home.

Troubleshooting Common Sewing Machine Issues

Sewing machines are essential tools for crafting and repairing garments, but encountering issues can be frustrating. Let’s explore some common problems and how to troubleshoot them.

| Issue | Possible Cause | Solution |

|---|---|---|

| Thread Breaking or Snapping | Tension too high or low, dull needle | Adjust tension settings and replace the needle |

| Uneven Stitches | Incorrect threading, bobbin issues | Re-thread the machine properly and check the bobbin |

| Machine Jamming or Skipping Stitches | Old or incorrect needle, tangled thread | Replace the needle with the correct type and check for tangled thread |

| Machine Making Unusual Noises | Loose parts, debris in the bobbin area | Tighten any loose parts and remove debris from the bobbin area |

| Fabric Not Feeding Properly | Incorrect presser foot, feed dog issues | Ensure the correct presser foot is used and check the feed dog |

| Bobbin Thread Tangling | Incorrect bobbin winding, bobbin tension issues | Rewind the bobbin correctly and adjust the bobbin tension |

Remember, regular maintenance, proper threading, and using the right needles can prevent many of these issues. If problems persist, consult your sewing machine manual for specific guidance.

Sewing Machine Maintenance Tips

Here are some top sewing machine maintenance tips:

- Cleanliness is Key: Regularly clean the machine to prevent lint buildup. Use a small brush to reach tight spaces.

- Change Needles Regularly: Worn-out needles can cause uneven stitches. Replace them after 8-10 hours of sewing or if you notice any damage.

- Oil the Machine: Keep your machine well-lubricated to ensure smooth operation. Use high-quality sewing machine oil and follow the manufacturer’s guidelines.

- Check Tension Settings: Adjust the thread tension as needed for different fabrics. Incorrect tension can lead to stitching problems.

- Inspect Bobbin Case: Check the bobbin case for lint and debris regularly. A clean bobbin area promotes proper thread tension.

- Thread Quality Matters: Use good-quality thread to avoid breakage and snags. Cheap threads can cause tension issues and damage the machine.

- Store Properly: When not in use, cover your sewing machine to protect it from dust. Store it in a cool, dry place.

- Follow the Manual: Always refer to your sewing machine’s manual for specific maintenance instructions. Different machines may have unique needs.

- Test on Scrap Fabric: Before starting a project, test your machine on scrap fabric. This helps identify any issues before working on your actual project.

- Professional Servicing: If you encounter persistent problems or if it’s been a while, consider getting your machine professionally serviced.

Conclusion

In conclusion of how to fix skipped stitches on sewing machine, we discussed that mastering the art of fixing skipped stitches is a vital skill for every sewing enthusiast. By identifying the root causes and employing the appropriate solutions, you can overcome this common sewing challenge with confidence. Whether it’s a simple adjustment to the needle, thread tension, or cleaning your machine, the solutions are within your reach.

As you embark on your sewing journey, let this guide be your trusted companion, helping you troubleshoot skipped stitches and elevate your sewing projects to new heights. With dedication and practice, you can enjoy the satisfaction of flawlessly stitched creations and unleash your creativity with a well-tuned sewing machine.

References

- Examination of alternative fabric joining techniques compared to traditional sewing

- A numerical investigation of the fluid mechanical sewing machine

- Measurement and analysis of needle penetration forces in industrial high-speed sewing machine

- Sewing machine selection for a textile workshop by using EDAS method

Frequently Asked Questions

What are some common causes of skipped stitches on a sewing machine?

Common causes of skipped stitches on a sewing machine include improper needle insertion, using the wrong type or size of needle, incorrect threading, and tension issues. Troubleshooting tips to address these problems involve checking and adjusting needle position, selecting the appropriate needle, rethreading the machine correctly, and ensuring proper tension settings.

How often should I check and replace the needle on my sewing machine?

Regularly checking and replacing the needle on a sewing machine is crucial to ensure smooth and accurate stitching. It is recommended to check the needle before each project or after every 8-10 hours of sewing to prevent skipped stitches and maintain optimal performance.

Can adjusting the tension on my sewing machine help to fix skipped stitches?

Adjusting tension can help troubleshoot skipped stitches on a sewing machine. By fine-tuning the tension settings, users can ensure that the upper and lower threads are balanced, preventing skipped stitches and achieving accurate stitching results.

What type of lubricant should I use to clean and lubricate my sewing machine?

To clean and lubricate your sewing machine, it is recommended to use a specialized sewing machine lubricant. This will ensure proper maintenance and smooth operation of the machine. Regular cleaning and lubrication are essential for optimal performance.

How can I test the stitch length and width on my sewing machine to ensure it is set correctly?

To test the stitch length and width on a sewing machine, adjust the settings according to the machine’s manual. Troubleshoot skipped stitches by checking needle size, tension, and thread quality. Adjust tension accordingly for different fabrics to ensure optimal stitching results.

How will you correct a skipped stitches problem?

If experiencing skipped stitches despite using the appropriate needle, thread, and technique, the solution involves removing and reinserting the needle. Ensure it is correctly inserted, not rotated, and firmly positioned to the top.

What is the cause of skip stitches in a sewing machine?

Skip stitches may result from a dull needle, occurring after approximately 7 hours of sewing. A needle that is dull, bent, or aged can lead to skipped stitches. It’s crucial to check the needle insertion, ensuring it is fully in place. If the needle is too low, it might be due to not loosening the screw adequately before insertion.

How do you fix a sewing machine that does not stitch?

To address a sewing machine not stitching, perform some quick checks. Verify that the bobbin winder shaft is not pushed to the right; if it is, move it to the left. Confirm correct threading by ensuring the threading line on the handwheel is at the top position, aligning the needle for proper threading.